Learn more with Glimek

Here you will find answers to some of the most frequently asked questions about Glimek's machines for dough handling and why you should choose a bread line or individual machines from Glimek for your bakery.

General Information about Glimek's Bread Lines and Dough Handling Machines

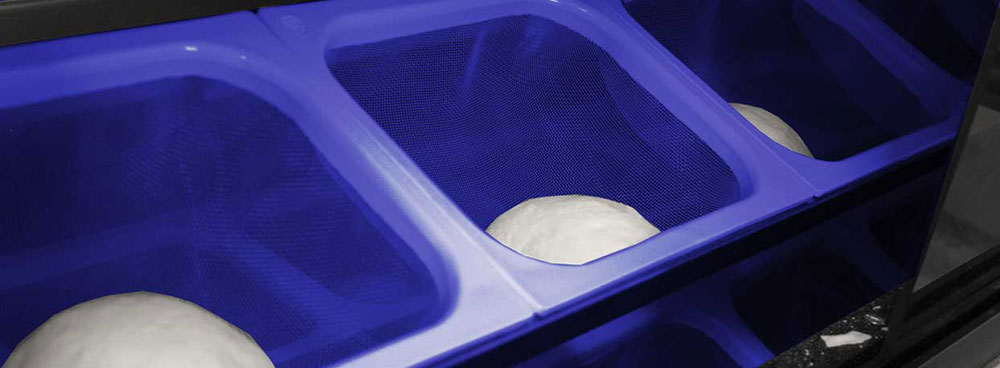

Why do we have blue plastic details on our dough machines?

The machines have blue details for food safety reasons. Glimek's dough handling machines have blue plastic details which makes it easy to see if any piece should go with the dough in the event of an accident.

Intermediate Proofers

When should you choose a Intermediate Pocket Proofer for your Bread Line?

A Intermediate Pocket Proofer is suitable for those who produce bread where the dough requires resting time. Glimek's Intermediate Pocket Proofer has adjustable speed, which means adjustable resting time. This allows you to easily change the time it takes for the dough to travel through the cabinet to suit different types of doughs and baked products.

When should you choose a Intermediate Conveyor Proofer for your Bread Line?

If you produce bread whose dough only needs a shorter resting time, a Intermediate Conveyor Proofer is recommended. An example of dough with a short resting time includes mixed doughs with rye and wheat flour. If you have a dough that does not need any rest, you can advantageously connect the Conical Rounder directly to the Moulder using a Cup Elevator.

Why is it important to have a stainless steel Intermediate Pocket Proofer, IPP?

A stainless steel Intermediate Pocket Proofer is easy to keep clean. The stainless surfaces are easy to wipe, which leads to high hygiene. With a stainless IPP, you can also feel secure that there will be no paint flakes or rust falling into the dough as could be the case with a painted cabinet.

How do I calculate how many effective pockets I need in my Intermediate Pocket Proofer, IPP?

To calculate how many effective pockets your proofing cabinet needs, use the following formula: Desired capacity (number of dough pieces per hour) / 60 x desired resting time in minutes = number of effective pockets.

Dough Dividers

Why you should have a volumetric Dough Divider from Glimek

All Dough Dividers from Glimek are volumetric. Being volumetric means that the dough is pulled down into the dividing chamber where it is cut with the right volume of dough depending on the setting.

This technique allows the dough to have different fermentation times and still get a perfect baking result because the pressure on the cut dough is adapted to the fermentation process. This approach gives a lighter crust and no, or very few, chemicals need to be added to the dough. When baking artisanal and more delicate breads, the volumetric method is preferred because the volume development is much better compared to other methods.

How do I clean and maintain my SD180 Dough Divider?

Follow below steps to clean and maintain your SD180 Dough Divider in a propper way.

Moulders

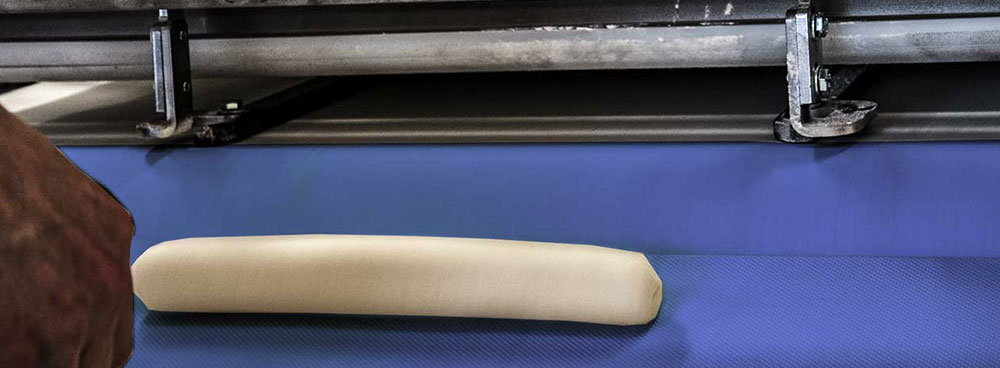

Why should you have a Moulder with a woven belt?

A woven belt absorbs moisture which means that the dough consistently maintains its consistency and is shaped in the best way. On other types of belts, moisture can accumulate which can lead to changes in the dough's consistency, becoming sticky and sticking.